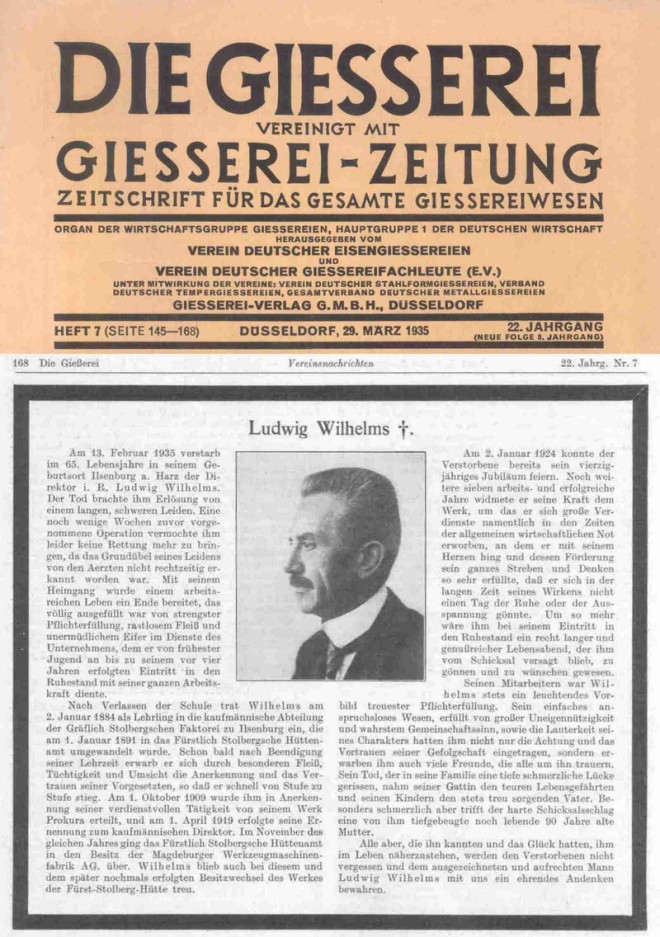

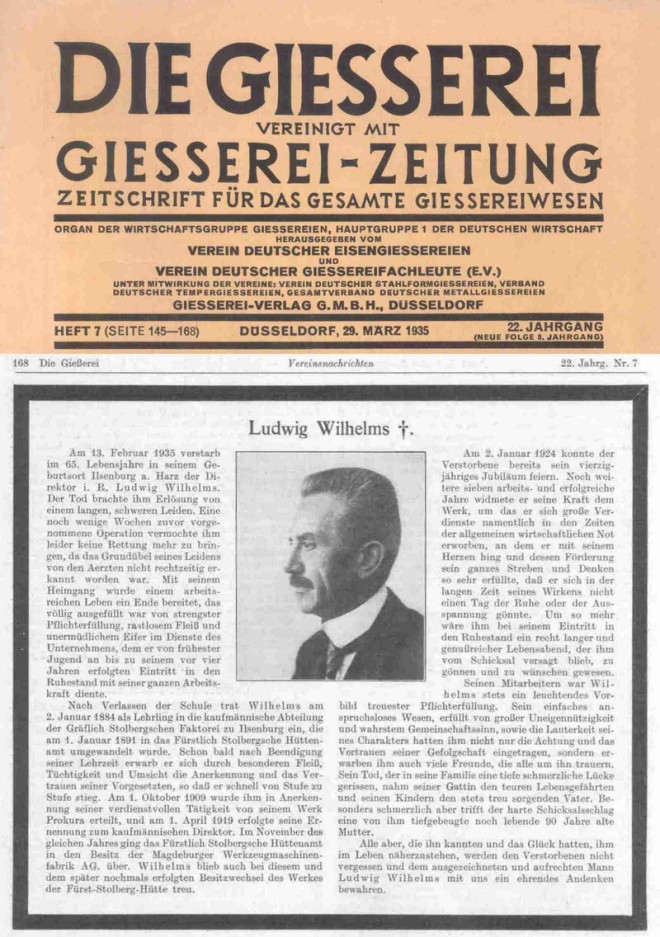

Ludwig Wilhelms (1870 – † 1935)

Ludwig Wilhelms (1870 – † 1935)

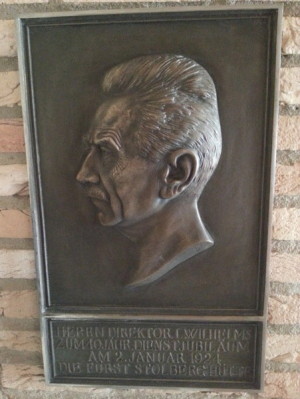

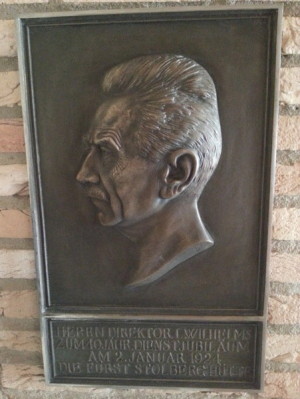

1924 40th anniversary of service

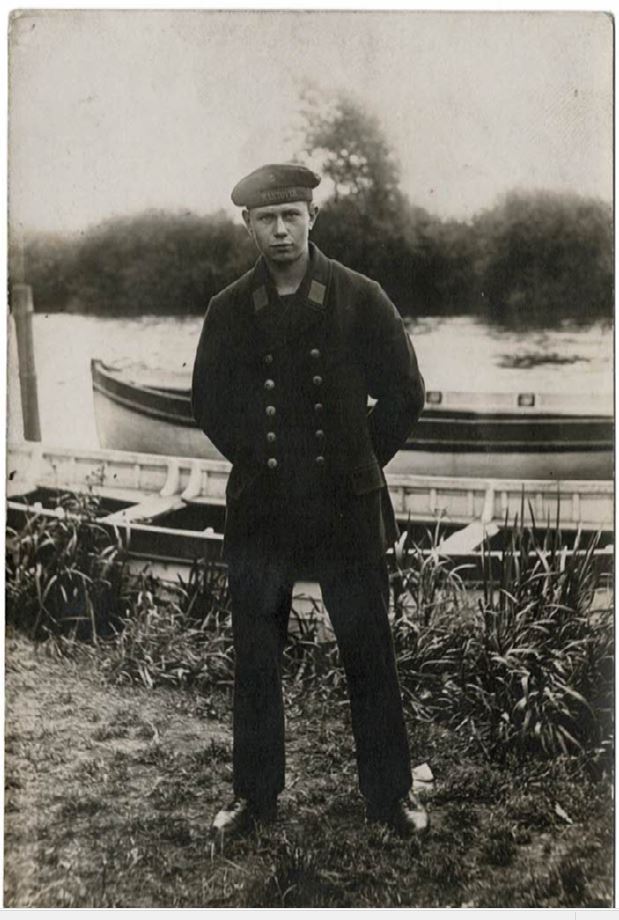

1919 – 1931 Director of the Fürst Stollberg Hütte

1909 power of attorney for the Fürst-Stollberg-Hütte

1884 Apprenticeship in the commercial department of the Fürst-Stollberg-Hütte

The Fürst-Stolberg-Hütte was world-famous for its cast iron. At the end of the 19th century she took part in many national and international exhibitions and achieved gold and silver medals with her products.

Great artists such as Albrecht Dürer, Karl-Friederich Schinkel, Alphons Mucha, Albin Müller, G. Wechter, Thorwaldsen, Labenwolf, Cellini, Petrucci, Holbein, Ferdinand Schneevoigt, Hermann Hase, Henning from Florence, Eduard Schott, Walter Schott, model tailor Ronung ( Stove plates from the 16th century, Master of the Queen of Sheba) created models for the hut or their work was used by the hut modellers as templates for true-to-the-original cast iron models.

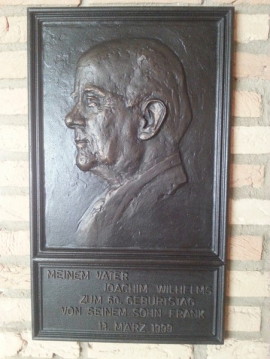

This anniversary portrait was made by Otto Wilhelms.

At that time, the Fürst Stollberg Hütte was very well known, which is why some famous people visited the hut. In 1697 Tsar Peter the Great visited the Ilsenburg ironworks, followed in 1873 by Crown Prince Friedrich, who later became Emperor Friedrich III. The German Emperors Wilhelm I and Wilhelm II also visited the Fürst Stolberg Hütte.

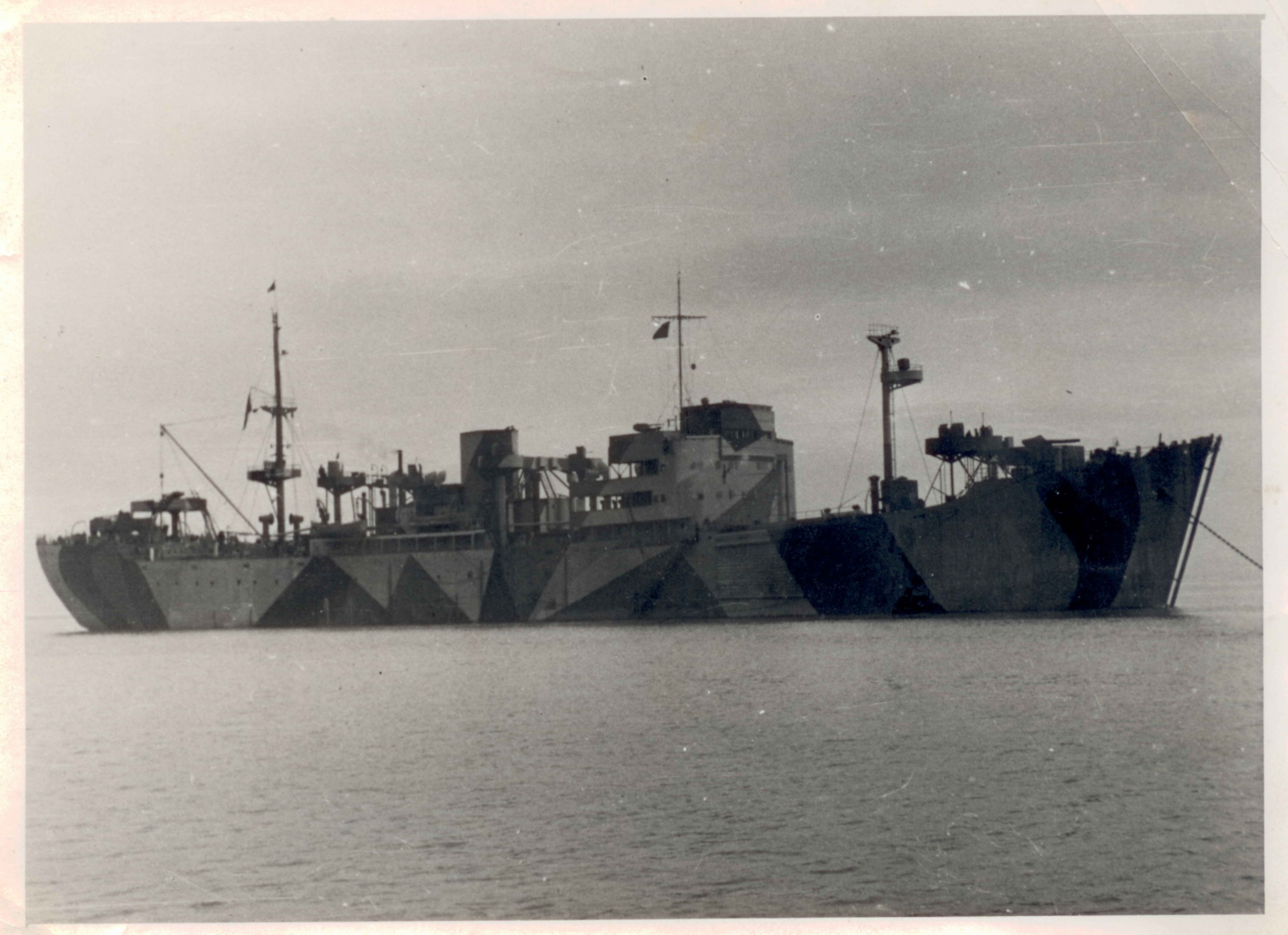

The last monarch to visit the  Iron Foundry.

Iron Foundry.

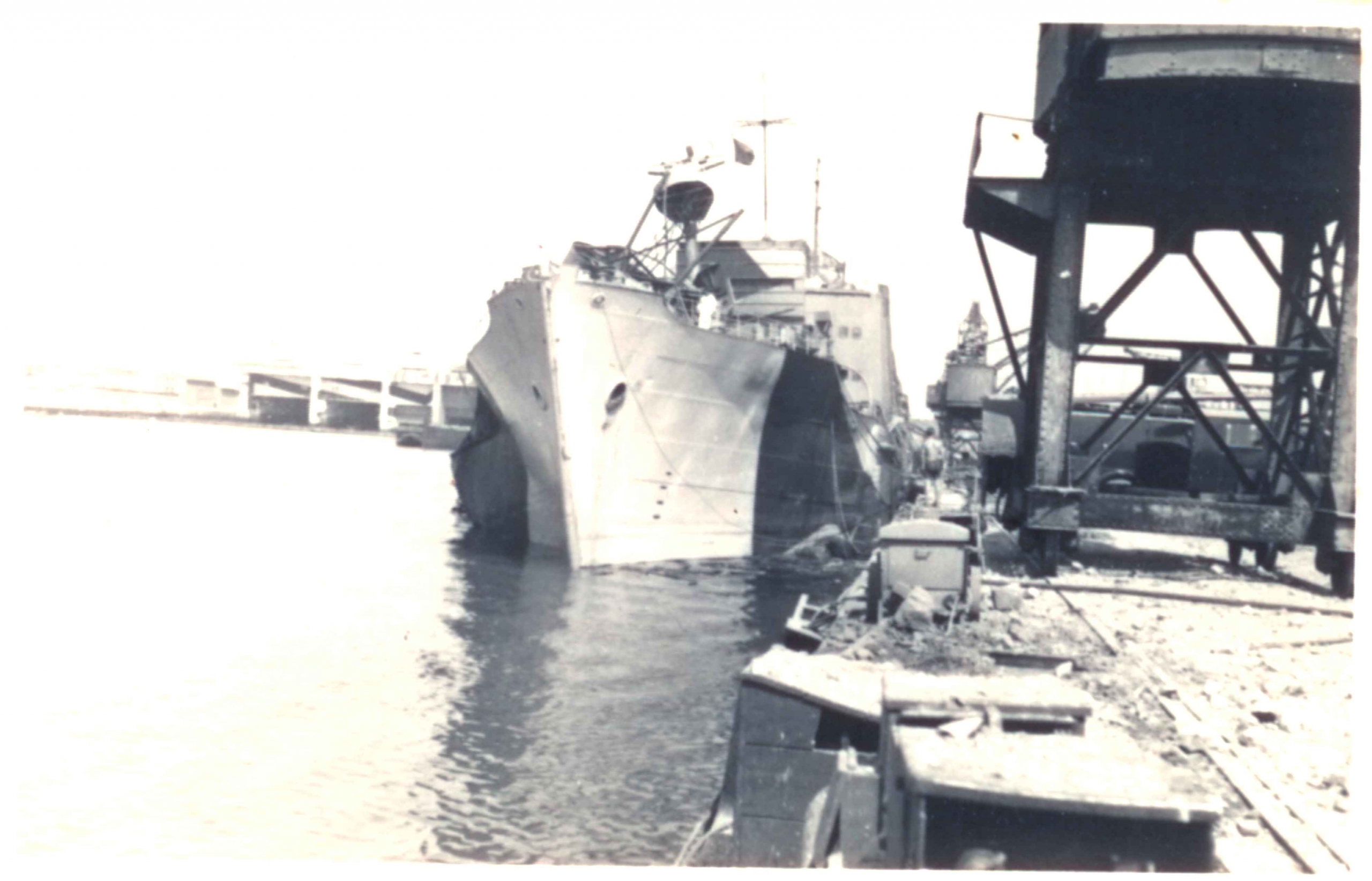

After the war from 1914 to 1918, the foundry passed into the hands of the Magdeburg machine tool factory in Magdeburg and was bought back by the Princes of Stolberg Wernigerode in 1925 and run again as the “Prince Stolberg Hütte”. At that time, the production of diesel locomotives, cranes, etc. was started. In 1930 the Krupp Gruson works in Magdeburg became the owner of the Fürst Stolberg Hütte.

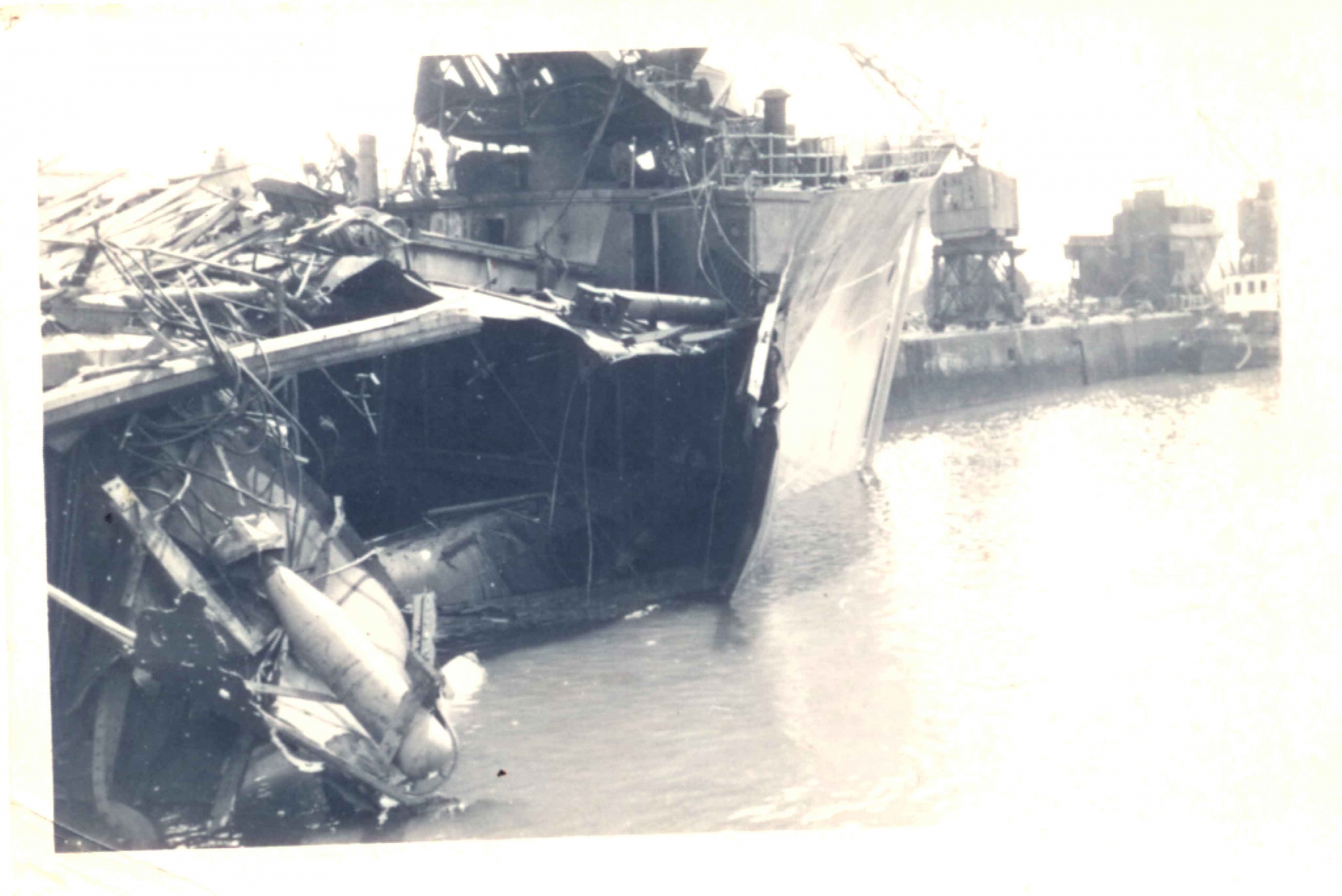

During the Second World War, the smelter produced war supplies with around 700 employees for other companies and was therefore also confiscated and expropriated in the course of the later Soviet occupation.

After the end of the Second World War, the Fürst Stolberg Hütte was nationalized, renamed Ilsewerk and produced exclusively industrial castings as a branch of the SKET Schwermaschinenbau Kombinate Ernst Thälmann.

In 1993 it was privatized under the traditional name “Fürst-Stolberg-Hütte” with a return to artistic casting until it was closed due to insolvency in 2012.

her GmbH).

her GmbH). < /a> er of ready-to-install large iron castings).

< /a> er of ready-to-install large iron castings).